Bricks have been one of the most commonly used construction materials for thousands of years. Over the years, the evolution of bricks has resulted in a plethora of options for construction in the market. Among these, cement bricks have seen a drastic upscale due to their versatility and wide range of benefits. These cement bricks are of two types- solid and hollow bricks. In this blog, we will discuss solid cement bricks in detail.

What are Solid Cement Bricks?

Solid cement bricks or solid concrete blocks are dense and heavy blocks made using a mixture of cement, sand and fine aggregates. They are ideal for large-scale buildings that require high-load-bearing walls. Compared to other bricks, these bricks are big and require less time and effort for construction.

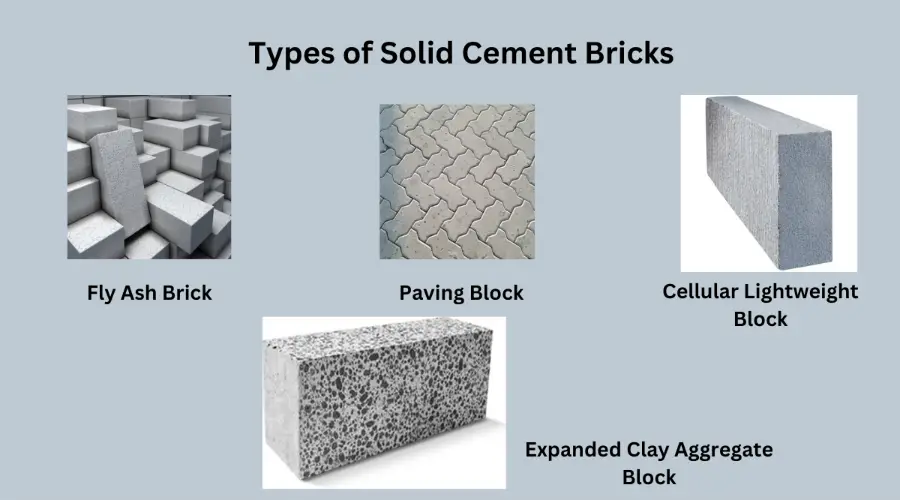

Types of Solid Cement Bricks

Fly Ash Brick

Fly Ash Bricks are made using a mixture of cement and fly ash as the raw materials. They are lightweight and can resist extremely high temperatures. These bricks are used both in residential and commercial construction. Due to their lightweight nature, they are only used for constructing partition walls and other non-load-bearing structures.

Paving Block

These blocks are mainly used for paving walkways, parking areas and on the shoulders of the road. These blocks come in various sizes and colours and are ideal for pavements.

Cellular Lightweight Block

Cellular Lightweight Blocks are made using cement, foam and fly ash. These are lightweight blocks similar to AAC and provide good acoustic and thermal resistance. These blocks are available in customisable shapes and sizes. The high-density cellular lightweight blocks can be used for load-bearing walls, while the medium-density blocks are used only for non-load-bearing walls.

Expanded Clay Aggregate Block

These blocks use cement and clay heated at high temperatures to provide a porous and lightweight material. These bricks are resistant to fire and water and reduce the overall structural load by 50%. The pores on the block act as a thermal and acoustic insulator for the structures. Since the clay is fired in a kiln, it can be moulded into different sizes and densities.

Advantages & Disadvantages of Solid Cement Bricks

Advantages

- Solid concrete bricks have high compressive strength, which makes them ideal for load-bearing walls and structures.

- These bricks are made using high-quality material and are designed to withstand all kinds of external impacts, making them durable and long-lasting.

- Solid cement bricks have excellent fire resistance properties that can be suitable for a structure that demands fire protection and in fireplaces.

- Solid cement bricks are available as half-bricks, thus reducing the damages caused by breaking the bricks for making bats.

- Using solid bricks in construction is very easy. They can be cut and drilled to the required sizes. The large size of the blocks reduces the time and energy for erection compared to other building materials.

- The solid blocks can be used for versatile purposes, including constructing walls, partitions, pavements and more.

Disadvantages

- Solid cement blocks are heavy and require careful handling.

- They have a higher water absorption rate and could easily get damaged in water-prone areas.

- The cost of solid concrete blocks is comparatively higher than other building materials.

- Although they have high compressive strength, these bricks have low tensile strength, thus making them vulnerable to cracks and chipping.

- The heavyweight nature of these bricks increases the overall structural load, which could demand heavier foundations.

- Constructing a wall using solid concrete blocks may not provide the same aesthetic look as bricks when left exposed.

Applications of Solid Cement Bricks

Foundations

Solid cement bricks are most commonly used for constructing the foundation, providing a strong and stable base. These bricks are strong, durable, and have high load-bearing capacity, making them ideal for laying foundations.

Walls

These bricks are used to build steady and durable walls for large structures. Due to their versatility, they can be used to build load-bearing, non-load-bearing, and partition walls.

Pavements

Solid cement bricks are used to lay pavements, walkways, parking, and shoulders of the road. Their brittle and durable nature helps them withstand high live loads and extreme climatic conditions.

Fireplaces

Due to the high fire resistance capacity of solid cement bricks, they can be used for fireplaces such as kilns, burning furnaces, manufacturing units, and structures that demand fire insulation.

Manufacturing Process of Solid Cement Bricks

Selection of Raw Materials

Raw materials such as cement, sand, and additives are carefully selected based on the quality requirements. The chosen raw materials are tested for consistency, size and chemical composition.

Mixing

After testing, adequate quantities of raw materials are batched according to the pre-determined standards. Additives such as fly ash or colour pigments can be added to the mix to achieve the required physical & chemical properties. The ingredients are then thoroughly mixed with water using mechanical mixing until they form a homogeneous mixture.

Molding & Compaction

The homogeneous mixture is poured into molds and compacted using vibrators or hydraulic presses to remove air voids and ensure proper filling.

Curing & Drying

After molding, the bricks are cured in a controlled environment using steam, water and air to improve hydration and strength. After curing, the bricks are removed from the mold and kept for air drying to remove excess moisture and enhance strength.

Installation & Maintenance of Solid Cement Bricks

Installation

- Pour the cement or lime mortar onto the surface with a 2.5 cm to 4 cm thickness to form a mortar bed.

- Lay the solid cement bricks over it and level them using a plumb bob and a wooden stick of approximately 1 meter in length.

- Apply the mortar onto the top surface of the first course and lay the second course of bricks, leaving enough space not exceeding 1 cm.

- Repeat the laying operations and check the horizontal and vertical levels using a plumb and a spirit level.

Maintenance

- Regular inspection is key in maintaining the concrete blocks, as numerous environmental factors could affect their structure. Early detection and repair could improve their lifespan and efficiency.

- Practice effective cleaning methods such as using cleaning agents and pressure washing to remove unwanted elements damaging the blocks.

- Address any cracks and damages on time and seal or repair them before they become a big issue.

- High-quality materials, proper installation, and coating can be used during construction and maintenance to extend the structure’s lifespan.

Conclusion

Solid cement bricks or solid concrete blocks are one of the strongest and most durable construction materials. They have numerous advantages over regular bricks and are highly durable against all kinds of external pressure, and proper installation can ensure the structure’s longevity. Although heavy and costly, they are worth the initial investment as they provide long-term benefits.