Brick is a significant building material used in a wide range of construction projects. They are primarily composed of resources like clay, concrete, and other materials. They can be used in both commercial and residential constructions, including building walls, pavements, and other structures.

They are available in various shapes, colours, and sizes, primarily known for their strength, durability, and fire-resistant properties. Bricks are categorised into various types, and this article carries some significant information about third-class bricks. Let’s delve into the topic and understand what third class brick is, its properties, and its advantages.

What are Third Class Bricks?

Third class bricks are low-quality bricks, which can’t be used everywhere like first or second class bricks. They are irregular in shape and size, have poor color uniformity, and have other significant defects. While dealing with any construction project, the strength and durability are the primary concerns of builders. If so, the quality standards of third-class bricks are not prominent and may be against the local building codes and regulations.

Characteristics of Third Class Bricks

Here’s how the characteristics of third-class bricks could be:

- Possessed with a non-uniform appearance, shape, and size.

- Unevenly or poorly burnt, which can mean overburnt or underburnt bricks.

- They are yellowish in colour and have round or distorted edges.

- They are weak in strength and durability.

- They have a compressive strength of 35-70 kg/cm² and absorption between 22-25 percent.

- Usually, bricks produce a metallic sound; however, they give a dull thud.

- These bricks are slightly soft, and the surfaces seem rough.

Properties of Third-Class Bricks

Third-class bricks are inferior in quality, which makes them unsuitable to use in construction. Let’s see some of their key properties:

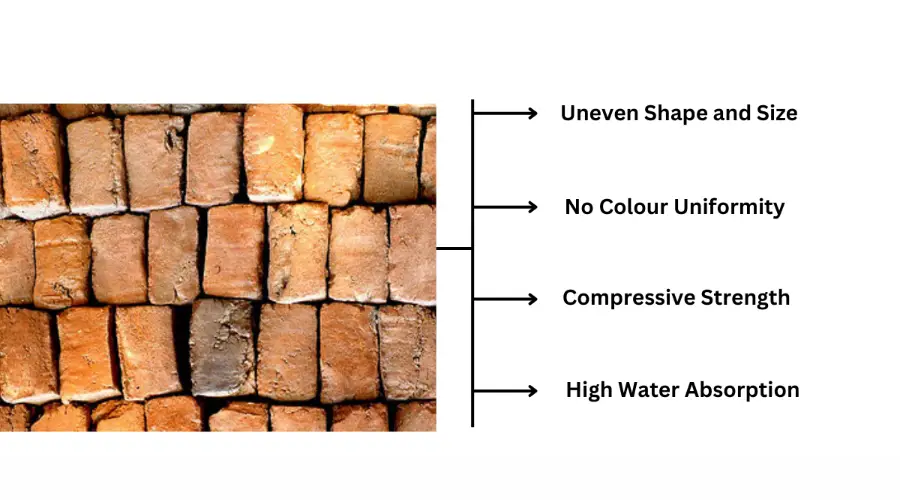

Uneven Shape and Size: Third-class bricks are either overburnt or underburnt. They look irregular in shape and size, which can significantly cause cracks, distortions, or other defects in the construction.

No Colour Uniformity: The colour of third-class bricks is irregular, indicating that they are overburnt or underburnt. It is one of the easiest ways to identify poor-quality bricks when buying them for your construction.

Compressive Strength: Its compressive strength is greatly lower than that of the first and second-class bricks (i.e., 3.5 N/mm²). Such a range negatively influences the strength and durability of the structures.

High Water Absorption: Low-quality bricks are subjected to absorbing more water, which makes them less suitable to use in areas with frequent rainfall or high humidity.

Advantages of Third Class Bricks

While third-class bricks are lower quality, they also offer some advantages in specific applications, including:

- They are cheaper than high-quality bricks. They can be a budget-friendly option for non-critical or non-load-bearing structures.

- Their irregular shape and size can give unique appeal to your decorative projects. While infusing creativity with third-class bricks, you can achieve unique patterns and designs in garden walls.

- They are soft in nature, which allows you to cut and shape them according to the construction requirements.

- Bricks are made from natural materials and cause less environmental impact compared to other materials.

Disadvantages of Third Class Bricks

They have several disadvantages, such as:

- They are not uniform in size or shape and may be slightly distorted.

- Third-class bricks are poor in quality and are sometimes overburnt or underburnt.

- They absorb nearly 20 to 25% of water by weight.

- Third-class bricks are not suitable to use in areas with high humidity temperatures.

- They can cause significant defects like cracks or distortions in the structures.

Quality Standards for Third Class Bricks

Third-class bricks offer poor performance in load-bearing structures. It possesses high water absorption rates, lower compressive strength, and poor durability when compared to first and second-class bricks.

It may be suitable for use in non-load-bearing structures as well as for decorative purposes. Other than that, it is advisable to consult the local building codes and regulations to ensure whether it is safe and suitable to use them in a particular construction project.

Manufacturing Process

Third-class bricks are manufactured by ground molding and burning in clamps. They are suitable for use in unimportant or temporary structures as well as for decorative purposes. The manufacturing process involves the following steps:

- Clay collection and storage is the primary step to do.

- Mix the clay with water and other essential materials to achieve the appropriate consistency.

- Pour the clay mixture into the molds to form bricks.

- Drying is the next crucial step, which needs to be done in an open sunny area.

- Once they are dried completely, burn the bricks in a kiln or clamp.

- Then let them cool down completely, and organize them by color and quality.

How to Identify Third Class Bricks

Here are some key characteristics to identify the third class bricks:

- They look non-uniform in shape and size, which can cause significant defects like cracks, chips, distortions, and other visible defects.

- They are softer and less dense, which is not suitable for use in load-bearing buildings.

- Their surfaces are literally rough with irregular and distorted edges.

- Unlike quality bricks, they produce a dull sound.

Practical Tips for Builders Using Third Class Bricks

Builders need to be aware of these information before using third-class bricks in construction such as:

Limited Applications: Third class bricks are low-quality bricks, and they are suitable to use only in temporary or non-load-bearing structures, including fencing, garden walls, or decorative features. It is better to ensure that they provide sufficient strength and longevity in the areas where they are used.

Use Reinforcement: If you decide to incorporate third-class bricks in your construction project, ensure that they are reinforced with quality materials like concrete or steel. They act as a strong support to compensate for the lower structural integrity, preventing potential damages.

Right Selection of Mortar: Analyzing the right mortar mix is essential to ensure the bonding and to avoid giving excessive stress to the third class bricks. Using lightweight mortar is advisable, instead of heavy-duty mortar, which is not suitable for low-quality bricks.

Moisture Content: Drying is the most typical part of the brick manufacturing process. It is essential to ensure that the third-class bricks are dried well to practically minimize the water absorption issues during the curing process. You can use protective coverings to avoid exposure to high humidity and rain.

Final Wordings

Third-class bricks are typically lower in strength, suitable only for use in inferior and temporary buildings. It is not advisable for use in areas that are subjected to heavy rains. While using them in any critical places, it is essential to verify the local building codes and regulations. Ensuring safety is a primary concern when dealing with any construction work.