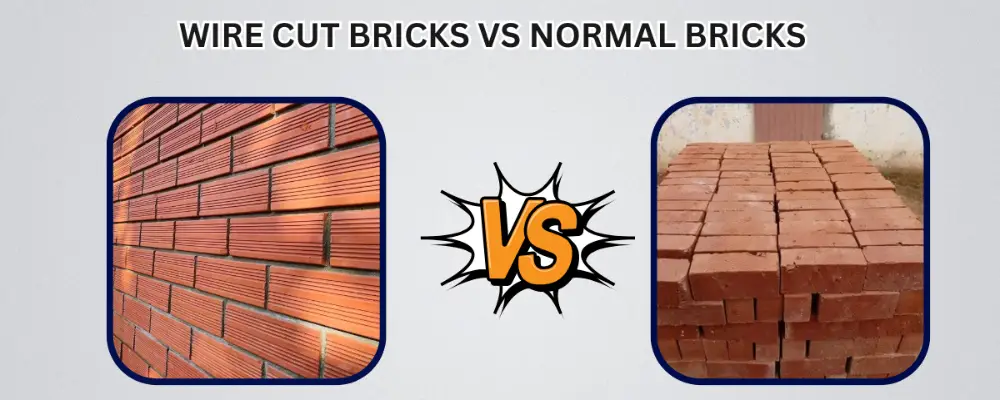

Choosing the right type of bricks for your construction is one of the most challenging aspects of a project. There are numerous brick types in the market, and each one has its unique characteristics. In this blog, we are going to compare the more modernised wire-cut bricks with the traditional brick, which has been in use for hundreds of years.

What are Normal Bricks?

Normal bricks are made using clay, sand, and other natural minerals. They are kiln-burnt and have high strength, resistance, and durability. Based on the grades, several types of bricks are widely used in the construction industry for walls, foundations, columns, and other structural and non-structural elements of buildings, including residential, commercial, and industrial buildings.

What are Wire Cut Bricks?

Wire-cut bricks are modern bricks made by extruding clay into a column and cutting it with a string to provide evenly shaped and sharp-looking bricks. These bricks are known for their precise shape, size, and consistency and are widely used for constructing load-bearing structures, exposed walls and other architectural purposes.

Key Differences Between Wire Cut Bricks and Normal Bricks

Manufacturing Differences

Wirecut Bricks

The manufacturing of wire-cut bricks is completely different from that of normal bricks. The raw materials, such as clay, sand, and aggregates, are fed into a pug mill (a stand-alone machine) and mixed into a plastic state. The plastic mix is fed into an extruder, where compaction is done to remove the air voids. The materials, after extrusion, are moulded using a die to attain the desired shape. Wires or long cables are used to cut the bricks into the desired sizes. The wire-cut bricks are then dried to remove moisture and set for hardening.

Normal Bricks

Traditional bricks are made by mixing raw materials such as clay, sand, and water, which are weathered and kneaded to form a homogenous mix. The raw material mix is then transferred to a mould in a plastic state and compressed to remove voids and gaps and to make the bricks denser. The bricks are then unmoulded and dried under the sun for three to ten days. They are then transferred to the fire kiln and heated at high temperatures. The bricks are then removed from the kiln and sorted based on the grades.

Cost Considerations

Wirecut Bricks

Wire-cut bricks require a higher initial cost compared to normal bricks. Manufacturing these bricks requires high-end equipment such as a ball mill and extruder, increasing production and selling costs. However, they are easy to maintain and reduce maintenance costs.

Normal Bricks

Normal bricks are cheap compared to wire-cut bricks. Their manufacturing cost is low as it doesn’t require costly equipment. These bricks are easily available at an affordable price. However, they need regular maintenance, especially when employed in external structures.

Strength and Durability

Wirecut Bricks

Wirecut bricks are stronger, more durable, and more resistant than normal bricks. They are also less porous and can withstand high moisture and poor weather conditions, which increases the lifespan of the structure.

Normal Bricks

Normal bricks have good resistance to fire, as they are burnt at high temperatures in the kiln. They are strong and durable; however, this depends on the brick grade. They have high water absorption and efflorescence rates, reducing the strength and lifespan of the structure.

Appearance

Wirecut Bricks

These bricks have sharp, clean edges and uniform appearance, and they are sliced with a wire after being extruded. The uniform looks, and clear-cut shape give it a more aesthetically pleasing and sophisticated look and also simplify the construction process.

Normal Bricks

The size and shape of the bricks depend on the moulding and burning process. First Class bricks have perfect shape and size, whereas the lower grade bricks could have slight undulations. These are traditionally used and provide solid looks.

Performance in Different Environmental Conditions

Wirecut Bricks

These bricks are highly resistant to weather and harsh climatic conditions, as well as moisture, heat, and ultraviolet radiation. However, although they have high resistance properties, they don’t provide the necessary insulation at varying temperatures.

Normal Bricks

These bricks are highly resistant to all climatic conditions and protect the structure from external heat. However, these bricks are vulnerable to moisture and water attacks, making them unsuitable for water-prone areas.

Thermal and Acoustic Properties

Wirecut Bricks

These bricks are resilient to heat and sound, acting as thermal and acoustic insulators. They help protect the building from external temperatures and noises entering the structure. It is one of the most preferred bricks where thermal and noise resistance are crucial.

Normal Bricks

These bricks are highly insulated against thermal forces, so they can survive fire and extremely high temperatures. However, they are not as good when it comes to acoustic insulation, as they are more dense, making it easy for sound to pass through the structure.

Pros and Cons of Each Brick Type

Wire-cut Bricks

Advantages

- High strength and durability.

- Sharp and smooth finish, making it aesthetically pleasing.

- Resistant to fire and sound.

- Wide range of colours, dimensions and textures.

- Low maintenance, reducing maintenance costs.

- Faster installation, improving the construction speed.

- Requires less mortar for masonry works.

Limitations

- It requires expensive equipment for manufacturing, increasing manufacturing costs.

- Requires skilled labour for installation and manufacturing.

- Insulation is limited at extreme temperature variations.

Normal Bricks

Advantages

- High strength & durability.

- Good weather resistance.

- Easily available and affordable.

- Absorbs sound, acting as acoustic insulation

- It is a natural thermal insulator that protects the structure from external temperature.

- Suitable for almost all types of construction

Limitations

- The manufacturing process pollutes the air

- Heavy weight

- Loss of soil & water

- Waste generation

How to Choose the Right Brick for Your Project?

Numerous factors need to be considered before choosing the right brick type for your project. These include the project goal and style, brick type, colour and texture, durability, strength, climate and weather resistance, sustainability, maintenance, budget and cost, local building codes and regulations, and availability.

Before making your choice, obtain the brick samples and test the bricks. If testing is impossible, consider consulting experts.

Conclusion

Both normal bricks and wire-cut bricks are great construction materials. They have a lot of similarities among them; on the other hand, they each have their unique characteristics. Wire-cut bricks provide a blend of durability, aesthetic appeal and sustainability. On the other hand, normal bricks are proven to be the best fit for construction due to their load-bearing capacity and variety of applications. On the flip side, wire-cut bricks are costly and require skilled labourers for installation. Normal bricks don’t provide aesthetically pleasing looks, and construction is time-consuming. Both the bricks have their ups and downs; the final decision of choosing between them is based on the construction needs.